Why am I writing about this now? Well, although there are definitely articles out there on cost variances, it seems like most of them are from the pre-9.0 world or have not been completely updated correctly. So, after a lovely chat with Pam Peterson at Microsoft today, I thought...heck, why not, let's lay it all out for everyone!

In the purchase order processing training manual, there is a section (at the end of Receivings Transaction Entry) that outlines three different kinds of cost variances related to FIFO/LIFO perpetual items. Here they are in a nutshell.

Scenario #1

- Item has a quantity on hand of 5 with a current cost of $1

- A quantity of 15 is sold, causing the item to go negative, this sale would be recorded with a unit cost of $1

- So, in the IV10200 (Inventory Purchase Receipts table), you would now have an override layer for the amount that was overriden (in this case, 10)

- A quantity of 20 is now received and invoiced in purchasing, with a unit cost of $1.25

- This creates a variance of $2.50 (.25 variance X 10) for COGS and Inventory

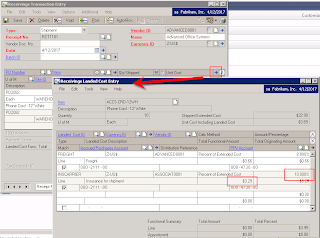

- This variance will print on the Cost Variance Journal when the receipt is posted

- Now, here is where it gets tricky...

- In GP 8.0 and earlier, this variance would NOT be automatically created in the GL

- In GP 9.0 and later, this variance IS automatically created in its own GL entry

Scenario #2

- Item has a positive quantity on hand of 10

- A quantity of 10 is received in purchasing, with a unit cost of $1

- A quantity of 10 is then invoiced in purchasing, with a unit cost of $1.25

- This results in a $2.50 variance between the original cost posted and the the invoice (.25 variance X 10)

- In this case, the difference is handled in the posting of the invoice. It will be recorded to the inventory account or to the purchase price variance account (depending on if revalue has been selected on the Item Purchasing Options, Cards-Inventory-Item Purchasing Options).

- The Purchasing Invoice Cost Variance Journal will print to detail the variance and will note that no manual adjustment needs to be made to COGS/Inventory.

- Item has a positive quantity on hand of 10

- A quantity of 10 is received in purchasing, with a unit cost of $1

- A quantity of 15 is sold to a customer, with a unit cost of $1

- A quantity of 10 is then invoiced in purchasing, with a unit cost of $1.25 (price to customer $3/each)

- This results in a $1.25 variance between the original cost posted and the the invoice (.25 variance X 5)

- In this case, the difference is also handled in the posting of the invoice. It will be recorded to cost of goods sold, inventory, and purchase price variance (if the item is not marked to revalue).

- The Purchasing Invoice Cost Variance Journal will print to detail the variance and will note that no manual adjustment needs to be made to COGS/Inventory.

For more information on the GL entry that is created by the variances, refer to TK #2448193. And for more information on cost variances and perpetual valuation methods, including average perpetual, refer to this article.

Christina Phillips is a Microsoft Certified Trainer and Dynamics GP Certified Professional. She is a supervising consultant with BKD Technologies, providing training, support, and project management services to new and existing Microsoft Dynamics customers. This blog represents her views only, not those of her employer.